Maintaining a nail gun used with plastic collated framing nails is essential to ensure optimal performance, longevity, and safety.

Here are some best practices for maintaining a nail gun:

- Regular Cleaning:

- Keep the nail gun clean by regularly removing dust, debris, and buildup from the magazine, nosepiece, and feed mechanism. Use compressed air or a soft brush to clean the interior and exterior surfaces of the nail gun.

- Lubrication:

- Apply lubricating oil to the moving parts and mechanisms of the nail gun according to the manufacturer’s recommendations. Lubrication helps reduce friction, prevents corrosion, and ensures smooth operation of the nail gun.

- Inspecting for Damage:

- Periodically inspect the nail gun for signs of wear, damage, or malfunction. Pay attention to the trigger, safety mechanism, magazine, and other critical components. Replace any worn or damaged parts promptly to prevent accidents or malfunctions.

- Adjusting Depth of Drive:

- Adjust the depth of drive setting on the nail gun as needed for different materials and applications. Proper depth adjustment ensures that nails are driven to the correct depth without over-driving or under-driving, resulting in secure and professional-looking fastening.

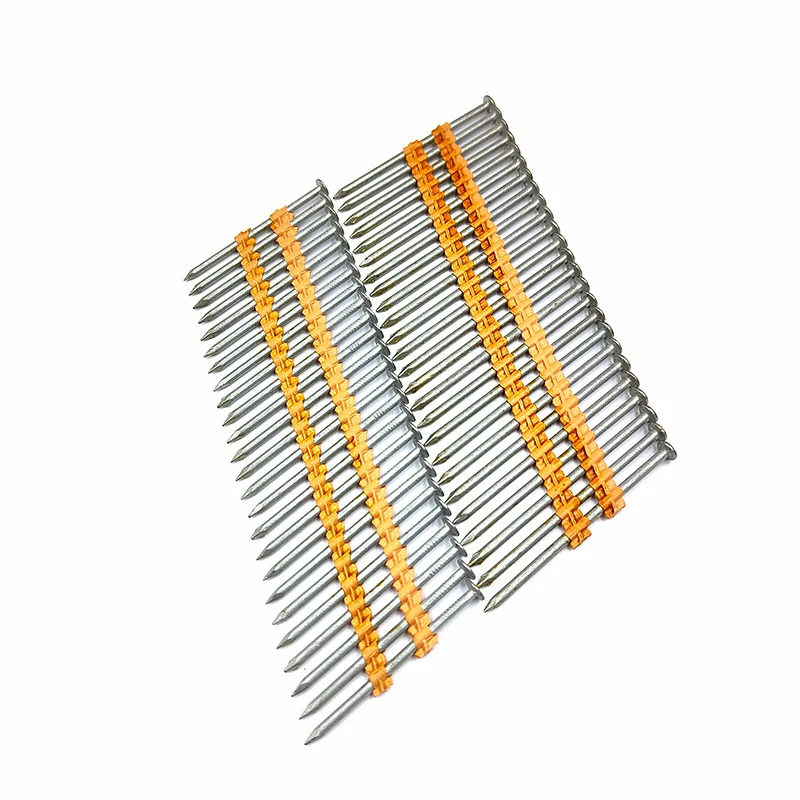

- Using Compatible Fasteners:

- Use only compatible plastic collated framing nails recommended by the manufacturer for your nail gun model. Using incorrect or incompatible fasteners can cause jams, malfunctions, or damage to the nail gun.

- Proper Loading:

- Load plastic collated framing nails into the magazine of the nail gun according to the manufacturer’s instructions. Ensure that the nails are aligned correctly and that the magazine is not overfilled to prevent feeding issues or jams.

- Storage and Transport:

- Store the nail gun in a clean, dry, and well-ventilated area when not in use. Avoid exposing the nail gun to extreme temperatures, moisture, or direct sunlight, as these conditions can affect its performance and durability. Use a carrying case or protective cover when transporting the nail gun to and from job sites.

- Safety Practices:

- Follow all safety guidelines and instructions provided by the manufacturer and outlined in the nail gun’s user manual. Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and gloves, when operating the nail gun.

- Regular Maintenance Checks:

- Conduct regular maintenance checks on the nail gun to ensure that it is functioning correctly and safely. Inspect the nail gun for loose or damaged parts, signs of wear, and any other issues that may affect its performance.

- Professional Servicing:

- If you encounter any problems or issues with the nail gun that you’re unable to resolve, seek professional servicing from an authorized repair technician or service center. Attempting to repair or modify the nail gun yourself may void the warranty and compromise safety.

By following these best practices for maintaining a nail gun used with plastic collated framing nails, you can prolong its lifespan, minimize downtime, and ensure safe and efficient operation on job sites. Regular maintenance and proper care contribute to reliable performance and high-quality results when fastening with a nail gun.